Improving Equipment Performance in the Textile Industry with Digital Inclinometers

The application of digital inclinometers in the textile industry can help enhance the quality and efficiency of production processes. Below, we explore some possible uses for digital inclinometers in the textile industry:

1- Precise Machine Adjustment

Digital inclinometers can be used to adjust and calibrate textile industry machinery, leading to greater accuracy in various stages of the production process.

Cutting and Sewing:

During cutting and sewing stages, the angle precision of machines is crucial. Digital inclinometers can assist operators in correctly adjusting machine angles, preventing imbalance or misalignment.

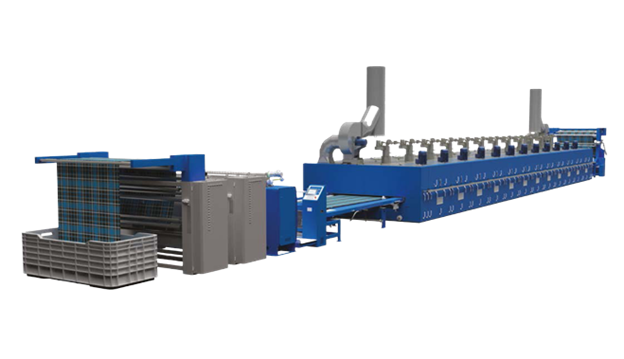

Weaving Machine Adjustment:

When setting up weaving machines, using inclinometers can help ensure precise adjustments and prevent defects in the fabric.

2- Monitoring Production Processes

Fabric Angle Monitoring:

During production, monitoring the angle and tilt of the fabric can help identify any imbalance that could lead to stretching or skewing.

Pressure and Load Control:

In some textile machines, the pressure and load applied to materials must be maintained at a specific angle. Digital inclinometers can assist in monitoring and adjusting these pressures.

3- Optimizing Production Lines

Waste Reduction:

By monitoring tilt and angle during the production process, it is possible to identify and correct issues before they lead to increased waste.

Productivity Enhancement:

By analyzing various angles in production lines, routes and production times can be optimized, leading to increased productivity and reduced costs.

4- Accident and Damage Prevention

Using monitoring tools like inclinometers can help identify risks related to machine misalignment or imbalance and prevent accidents. Ensuring the correct condition of machines and avoiding overloads increases workplace safety.

5- Maintenance

Maintenance Planning:

Data obtained from inclinometers can help develop preventive maintenance schedules, including replacing parts before failures occur.

Data Analysis:

By analyzing angle changes over time, behavioral patterns can be identified, and maintenance strategies can be tailored to the specific needs of each machine.

Reducing Equipment Wear:

By maintaining optimal conditions, equipment wear can be reduced, extending their lifespan.

Conclusion

Digital inclinometers are valuable tools in the textile industry that aid in process optimization, quality control, and enhancing production accuracy. Utilizing this technology can lead to improved quality standards and reduced production costs.