Monitoring and Correcting Rail Bending in the Rail Industry

Applications of Inclinometers in the Rail Industry :

Inclinometers have two primary functions in the rail industry:

- Monitoring the proper installation of rail lines

- Long-term monitoring and control of rail bending

Below is a brief description of each application:

Monitoring Proper Installation of Rail Lines:

During the construction and installation of rail tracks, inclinometers can play a crucial role. One of the most sensitive and important factors in rail track construction is the alignment between the two rail lines along the route.

Figure1

Figure2

Using Digital Inclinometers to Measure Rail Alignment:

Solution:

To measure the alignment of two rail lines, a digital inclinometer along with a precise horizontal holding rod, as shown in Figure 2, can be used. For this purpose, digital inclinometers with a low measurement range, high accuracy, and thermal stability are required to be effective in operational environments. A significant point in using inclinometers in the rail industry is the environmental temperature variations in different seasons and times. Therefore, it is crucial that the sensors have high thermal stability to maintain their accuracy under diverse temperature conditions.

Long-Term Monitoring and Control of Rail Bending:

Over time, particularly due to high train speeds, weather impacts, and structural fatigue, rails can bend. If this issue is not properly monitored and managed, it could lead to rail accidents.

Figure3

Figure4

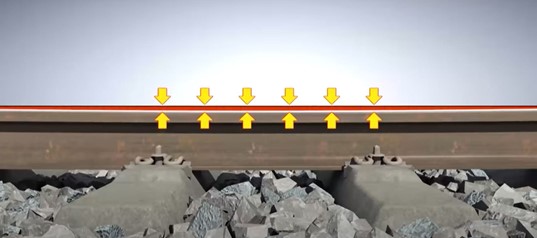

As shown in Figure 3, the passage of rail vehicles generates a high dynamic force that applies stress to the rails. The continuous stress causes the rails to gradually deviate from their original position and bend (as indicated by the red line in Figure 3). If the damage becomes excessive, to prevent harm to the rail vehicle and its passengers, the concrete base under the rails must be refilled with stone and sand. This process is called tamping, and the machine used for this purpose is known as a tamping machine. Figure 4 illustrates how this process is performed. The key issue is detecting the extent and severity of the deviation in order to timely repair and restore the rails, thus preventing serious damage to rail vehicles and passengers.

Using Inclinometer Bases to Assess Rail Bending

Solution:

To detect the severity of rail deviation, two methods can be used. In the first method, a digital inclinometer and a mechanism like the one shown in Figure 5 are used to move along the rails and determine the angle of deviation and misalignment. After detection, the position of the deviated rails and the precise amount of deviation are reported to the tamping machine.

Figure5

Figure6

As a second solution, an inclinometer sensor (instead of a digital inclinometer) can be used. Inclinometer sensors allow for continuous monitoring without the need for constant inspections and additional manpower. The sensor data can be sent to the rail control center, providing continuous monitoring of the rail lines’ condition. As a result, negative impacts such as rail bending or ground settlement due to time or rainfall, etc., will be permanently monitored. Using continuous monitoring with inclinometer sensors significantly increases the safety factor of the rail system.